Pipe Components

PTFE Maximum Chemical Resistance

Without question, PTFE (polytetrafluoroethylene) offers the broadest capabilities of any commercially available material. In Durcor® pipe, it will handle temperatures up to 300ºF and resist:

Without question, PTFE (polytetrafluoroethylene) offers the broadest capabilities of any commercially available material. In Durcor® pipe, it will handle temperatures up to 300ºF and resist:

PTFE also has incredible non-stick properties which eliminate and/or minimize deposits on pipe wall.

Durcor®’s seamless PTFE liners exceed the requirements of ASTM F1545 where applicable. Liner thickness ranges from .130” for 1” pipe to .310” for 8” diameter piping. Durcor®’s thick and strong liners aid in permeation resistance and are able to withstand full vacuum conditions throughout its full temperature range.

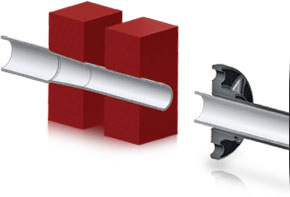

Thermosized™ PTFE Liners

Durcor®’s thick, free standing PTFE liners undergo a battery of tests designed to ensure liner integrity prior to being positioned into its structural composite housing. Durcor®’s unique Thermosizing process combines the PTFE liner into the composite pipe. An additional heating cycle then relaxes the liner for a snug, interference fit within the composite housing. The Thermosize technique provides PTFE dimensional stability under pressure, vacuum and temperature cycling conditions.

Durcor®’s thick, free standing PTFE liners undergo a battery of tests designed to ensure liner integrity prior to being positioned into its structural composite housing. Durcor®’s unique Thermosizing process combines the PTFE liner into the composite pipe. An additional heating cycle then relaxes the liner for a snug, interference fit within the composite housing. The Thermosize technique provides PTFE dimensional stability under pressure, vacuum and temperature cycling conditions.

- Resin-rich outer layer provides corrosion and abrasion barrier. The barrier surface provides excellent chemical resistance from hostile environments and corrosive soils that can attack carbon steel. The additional layers add protection against glass blooming caused by ultraviolet radiation from sunlight.

- Glass matrix mass fully saturated with vinyl ester resin provides excellent impact resistance.

- Axial glass roving filament bundles in linear direction provide exceptional stiffness and better span capabilities with near-zero thermal expansion.

- Continuous bundles of reinforcing glass roving is wrapped radially over inner veil to provide outstanding hoop strength for 4:1 pressure safety factor.

- Multiple inner layers of resin-rich veil provide superb corrosion barrier to reinforcing roving bundles.

- PTFE liner thickness exceeds the requirements of ASTM F1545 and is full vacuum rated in all sizes to +300°F.

| Typical Properties of Durcor® PTFE Liner | |||

|---|---|---|---|

| Property | Test Method | Unit | Value |

| Tensile Strength | ASTM D638 | PSI | 3,500 |

| Ultimate Elongation | ASTM D638 | % | 250 |

| Izod Impact Strength @ (-)40ºF | ASTM D256 | ft-lb/in | 1.5 |

| Izod Impact Strength @ (+)75ºF | ASTM D256 | ft-lb/in | 3 |

| Hardness, Durometer | ASTM D2240 | Shore D | 55 |

| Thermal Conductivity | ASTM E1530 | BTU-in/hr-ft2_oF | 1.7 |

| Dielectric Strength | ASTM D149 | V/mil | 600 |

| Surface Resistivity | ASTM D257 | ohm-sq. | >1018 |

| Water Absorption | ASTM D570 | % | <0.01 |

| UL 94 Flame Rating | 94 V-0 | ||

| Static Coefficient of Friction | 0.05 | ||

| Specific Gravity | 2.14 – 2.19 | ||

| Typical Properties | ||||

|---|---|---|---|---|

| Typical Physical Properties | 75°F | 250°F | Typical FRP @ 75°F | Method |

| Axial Tensile Strength | 48,000 psi | 31,200 psi | 11,600 psi | ASTM D2105 |

| Axial Tensile Design Strength | 12,000 psi | 7,800 psi | 3,870 psi | ASTM D2105 |

| Axial Modulus of Elasticity | 2.76 × 106 psi | 1.70 × 106 psi | 1.60 × 106 psi | ASTM D2105 |

| Axial Compression Strength | 50,750 psi | 34,075 psi | 14,500 psi | ASTM D695 |

| Axial Compression Design Strength | 12,690 psi | 8,520 psi | ASTM D695 | |

| Compression Modulus | 2.39 × 106 psi | 1.47 × 106 psi | ASTM D695 | |

| Beam Bending Ultimate Stress | 47,100 psi | 35,300 psi | 12,380 psi | ASTM D2925 |

| Beam Bending Design Stress | 5,900 psi | 4,410 psi | 4,410 psi | ASTM D2925 |

| Poisson's Ratio | 0.32 | 0.65 | ||

| Flexural Modulus of Elasticity | 3.26 × 106 psi | 1.89 × 106 psi | 1.81 × 106 psi | ASTM D790 |

| Coefficient of Linear Thermal Expansion | 6.7 × 10-6 in/in/°F | 10 × 10-6 in/in/°F | ||

| Specific Gravity | 1.92 (housing) and 2.15 (PTFE) | 1.80 | ||

| Heat Deflection Temperature | 266 °F | |||

| Hazen-Williams Flow Coefficient | 155 | 150 | ||

| Thermal Conductivity | 0.7 BTU-in/hr-ft2_oF | |||

Durcor

Durcor